Mold Design Features

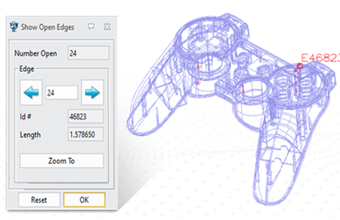

Data Repair

Accurately analyze and repair various geometric topological issues, including cracks, open edges, etc. Efficiently process model gaps and reconstruct missing faces to ensure a complete model and data quality.

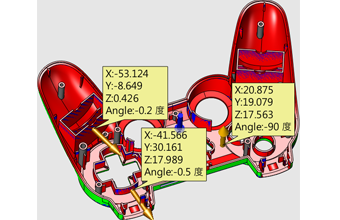

Manufacturability Analysis

You can check and verify the manufacturability of product structures with tools such as Draft Analysis, Thickness Analysis, and Undercut Analysis. Also, intuitive analysis.

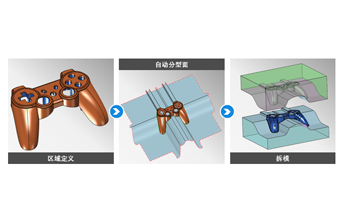

Fast Parting

The core, cavity, and other areas can be defined through parting lines or parting faces. Various handy tools are available for holes and parting faces creation, making it simple and clear to transform from the product to core and cavity.

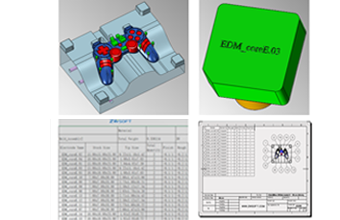

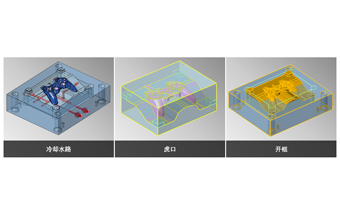

Specialized Tools for Mold Design

Specialized tools are provided to quickly create runners, cooling systems, slide and groove, which can also be easily and intuitively modified.

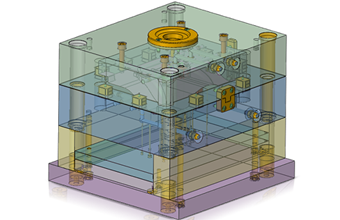

Mold Standard Parts Library

The built-in library of mainstream mold bases and standard parts (MISUMI/FUTABA/HASCO/DME/LKM, etc.) are provided and user can create and customize their own standard part library.

Auto Mold Drafting

Mold attributes can be automatically recognized. The engineering drawings of all components can be generated effortlessly according to the predefined type template while dimensions can be automatically added according to custom settings.