Hybrid Modelling in ZW3D: A Highly Flexible Modelling Technology

If you are working on product design with a 3D CAD system, you must know the technology of hybrid modelling, which combines surface modelling and solid modelling methods in one CAD system, and is usually applied to product prototype design or structural design. However, it’s more than a simple combination. What’s the meaning of “hybrid”? Have you ever probed into this concept? Are the current solutions of hybrid modelling “hybrid” enough? To answer these questions, today, I would like to discuss this technology with you.

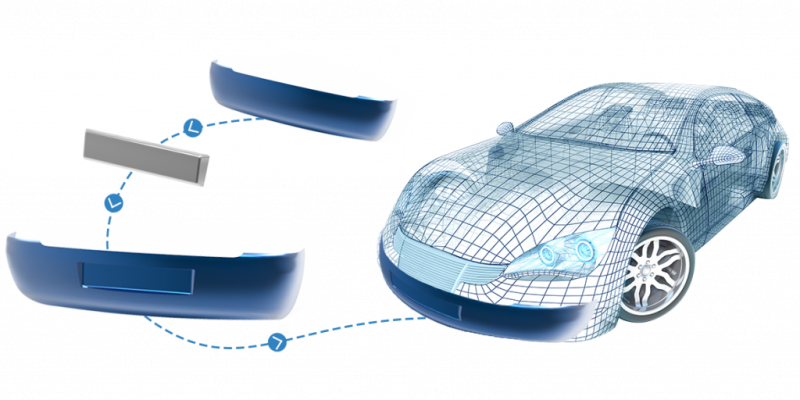

Figure 1. Apply solid-surface hybrid modelling to product design

Solid Modelling VS Surface Modelling

To help you clearly and completely understand hybrid modelling , I would first introduce solid modelling and surface modelling , which are two mainstream geometric modelling methods composing hybrid modelling .

Solid modelling emphasizes on physical fidelity, which represents an object precisely by describing its surface boundary and topological orientation so that we can completely tell the geometric and topological information of the object, including its vertex, edge, face, volume, etc. Solid models are parametric, offering accurate geometric data for editing, engineering analysis and production.

Figure 2. A model created by solid modelling method

In contrast, surface modelling describes an object’s exterior by surfaces, which have no thickness and allow overlaps and gaps. With this method, you can create external shapes of an object by stretching infinitesimally thin surfaces over it with 3D curves. Surface modelling is often applied to creating complex or streamlined products. Sports car design is the typical case.

Figure 3. A surface created by surface modelling method

To summarize, solid modelling describes shapes precisely, but it’s a bit time-consuming. Surface modelling creates shapes freely, helping to present products in the short term. However, its results lack the dataset needed for engineering.

Most Hybrid Modelling Methods are Not Hybrid Enough

The choices between solid modelling and surface modelling have plagued designers since the dawn of 3D CAD software. Now, most mainstream 3D CAD solutions have enabled hybrid modelling for engineers to utilize these two methods at the same time. They put solid modelling and surface modelling into one CAD environment, saving your time from switching software.

However, is it hybrid enough to just put these two methods in one CAD system? Think about this question when you need to sew or add thickness to the surfaces every time before turning them into solid, which is probably the most common situation you meet. Or recall those days when you buried in fixing your models before doing mold parting and splitting. If a hybrid modelling technology cannot support doing Boolean operations between solid and surface, it cannot truly satisfy users’ needs on product design.

Reading this far, you may wonder can these two modelling methods get truly integrated, achieving more flexible hybrid modelling ? In ZW3D, it’s not a daydream.

ZW3D Offers More Flexible Hybrid Modelling

Over the years, the ZW3D team has been working on deeply integrating surface and solid modelling to take full advantage of the strengths of both the two modelling technologies. With its OverdriveTM kernel, the Solid-Surface Hybrid Modelling technology is realized, enabling you to design really flexibly with solids and surfaces simultaneously. What are the unique benefits of hybrid modelling in ZW3D? Let’s see!

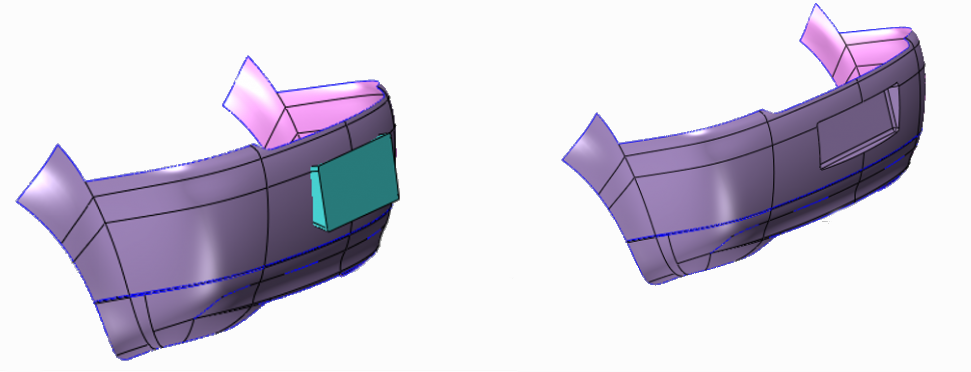

Doing Boolean Operations with solid and surface simultaneously, which means that you can cut surface with solid and cut solid with surface at the same time. For most 3D CAD software, designers can cut solids with surfaces. Is it possible to also cut surfaces with solids? Using Solid-surface Hybrid Modelling in ZW3D, this can happen. You can freely do Boolean operations, so that shapes or solids can be added to, removed from or intersected into surfaces to get the results you want.

Figure 4. Cut surface with solid

Most commands can be applied to both solids and surfaces. Normally, the commands of solid modelling and surface modelling are separated, which means that you have to learn all the commands and distinguish the differences between them, making your 3D modelling learning curve long. With Solid Surface Hybrid Modelling , this is no longer a burden. It eliminates the barrier between solid modelling and surface modelling , enabling you to use the same set of commands for both solids and surfaces. More convenient, right?

Figure 5. Abundant tools can be applied to both solids and surfaces

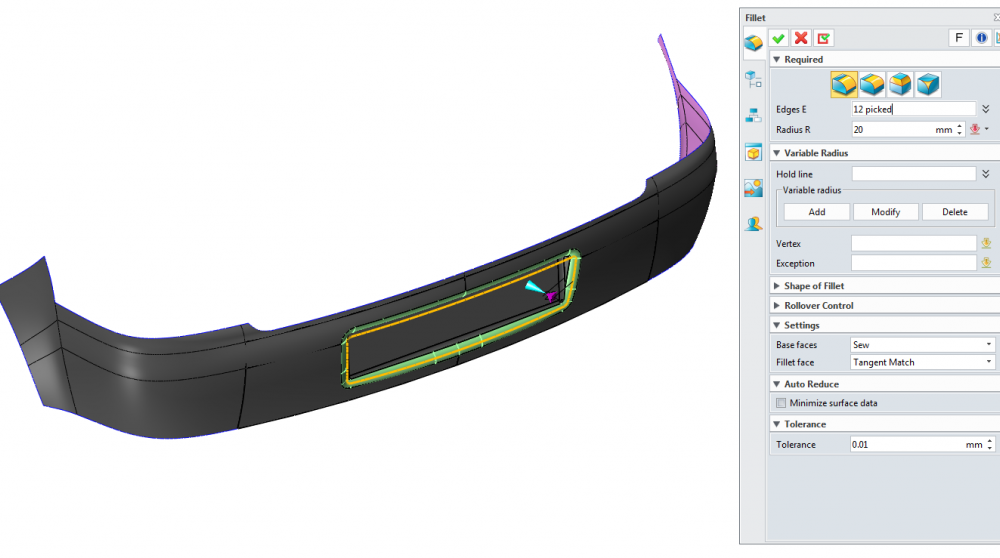

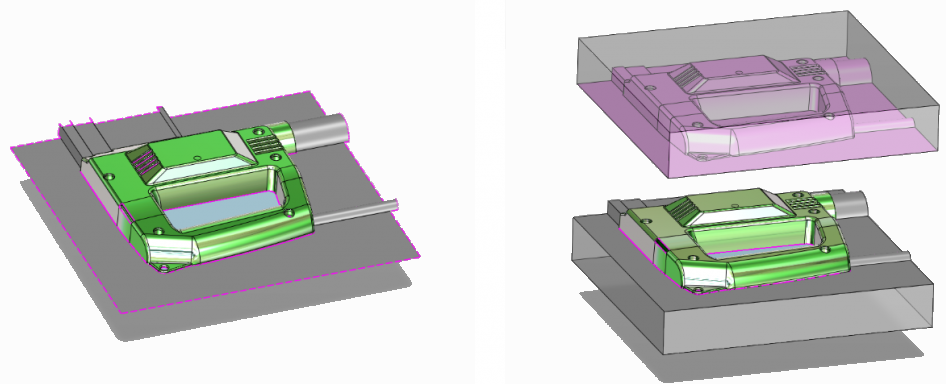

Figure 6. Apply Fillet command to a surface

Tiny imperfections won’t restrain your design. It’s common to get imperfect models after importing third-party data or when designing models with complicated structures. Normally, designers have to spend lots of time to make the models watertight before moving to next steps, which would be sometimes wearisome and time-consuming. We must admit that creating a perfect model is a good habit during design. But you don’t have to be a perfectionist all the time when the flaws are not key factors in specific design tasks. When the design flaws are within tolerance, we offer a chance to breathe in case you are trapped in healing models, leaving you more time for more important work. For example, you can do a quick mold parting in ZW3D even though the model is not completely watertight, winning time for quotation and increasing competitiveness.

Figure 7. Do mold parting when the model has a tiny gap

If you are bothered by too rigid solid modelling or insufficiently rigorous surface modelling or get frustrated sometimes to deal with tedious healing work in a not hybrid enough CAD space, I believe you could know the benefits of Solid Surface Hybrid Modelling in ZW3D once knowing how it works. Yes, more flexible, powerful, efficient. Fancy words may not be convincing in today’s market. But true solid-surface hybrid modelling can make a huge change to your work once you use it. If you still doubt it, why not have a try? Seeing is believing.